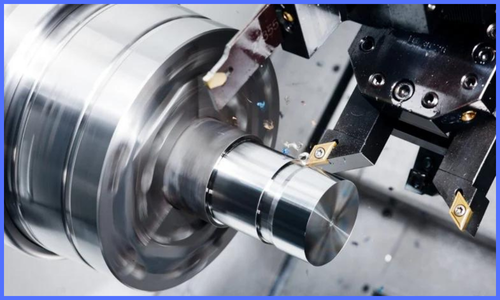

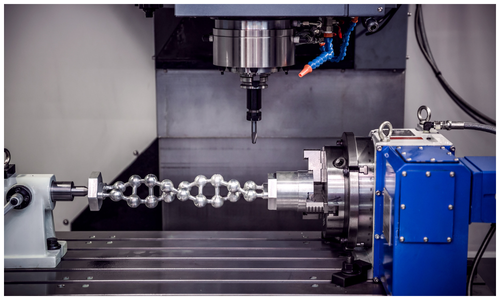

CNC Turning Programming Courses

Fanuc Control Programming

CNC Turning Machine Operating, Setting & Trouble-shooting

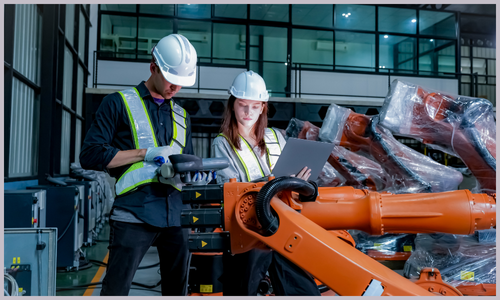

CNC Training course covers the advanced concepts of CNC Programming from the basics level.

with practrical training in our machine shop and 100 % job Placement after successful completion of course.

It is suitable for anyone wanting to learn the most common type of CNC programming, IT covers the principles of how turning machines work and a basic understanding of cutting tools. It gives an complete knowledge of turning process.

It also covers the basic measuring instruments used in CNC Turning.